|

|

1. Procurement of raw material (gold bar)

The gold bar used in gold leaf production must have purity of not less than 96.5% - 99.99% according to Thai standard for gold bar. We purchase from wholesale stores where are reliable according to the standard. However, we always do the sampling to check for gold purity (ASSAY) and receive the certificate issued by the qualified service company. |

|

|

| |

|

|

|

2. Gold foil and rolling process

After getting standard gold bar, then it will be brought to the shops where provide gold and silver rolling service. The gold bar will be rolled to have the width of 4.0 centimeter, the length is depend on gold weight, and the thickness around 4-5 micron. We call the rolled gold as gold foil. After that, we will wipe the greasy from the gold foil and then cut it into around 1 foot-piece to be easy in cutting to smaller pieces. |

|

|

| |

|

|

|

3. Gold beating

After getting clean gold foil, we will cut it into small pieces with the size of 1 centimeter-squares, which is called a cutch piece. This gold beating process can be done by general scissors which is sharp and used for cutting gold only. Each gold beating requires around 3 Baht-weight of gold and produces around 1,500 – 1,600 pieces of cutch. The cutch will be applied by a little gypsum powder. This process is called briming. |

|

|

| |

|

|

|

4. Preparation of cutch paper, softening, and cutch sweeping

Cutch paper is turbid cellophane imported from Japan and China. It is cut into 4 inch-squares which is called a cutch. Regarding the packaging process, 1 package requires 2 pieces or 1 pair of cutch with 1,000 pieces of cellophane in each piece of cutch. The cutch must be softened by coating with powder and beat around 2-3 times before use to soften the cellophane and prevent the delicate gold leave from sticking to the cutch paper. Then the gold cutting process can be started after receiving the cellophane. Moreover, the cutch must be cleaned by sweeping every time before gold beating process. This process is called cutch sweeping. |

|

|

| |

|

|

|

5. Cutch packaging

Once the cutch is ready, it will be packed with 1 piece of cellophane and 1 gold foil. Each gold foil must be placed at the middle of cellophane for easy notice and getting the similar shape of gold leaf. Then cover it by 2 layers of leather and bring it to hammering process. |

|

|

| |

|

|

|

6. Cutch hammering

Once receiving 2 pieces of cutch, they will be beaten piece by piece. The process start with beating until the cutch paper is sink and gold leaf spread because receipt of impact force from hammer until generating heat. The beating will be done softly around 20 minutes then increase the force to be heavy slowly. The beating must be done by switching to all sides to get round and good looking shape of gold leaf. The beating must be done around 12 cycles with 80 pieces in each cycle, then review the gold shape whether or not request decoration. One pair of cutch, which has 2 pieces, can be completed within two and half hours. Be careful about loosen leather cover which may cause the gold leaf break. |

|

|

| |

|

|

|

7. Preparation of packaging skin, skin coating, skin briming

Skin’s size is 6.5 inch-squares. Arrange 1,600 pieces of cellophane by covering with protection paper (the paper which is knocked by the hammer directly) of 200 pieces on each side. Totally, there are 2,000 pieces of protection paper in 1 package. Apply gypsum powder around 20 cycles by 2 hours in each cycle until the cellophane become mature, gross, and ready for application. In each time of gold leaf inserting, it must be clean by gypsum power. |

|

|

| |

|

|

|

8. Package inserting

Insert one pair of beaten cutch into a package, then beat for expansion. Package insertion is done for checking the cutch’s characteristics, necessity of decoration, and remove broken piece. Package insertion is similar to cutch insertion. The gold must be placed in the middle of cellophane to know the expand position of gold. When complete cutch insertion of two sides, then cover both sides with leather and transfer to hammering process. |

|

|

| |

|

|

|

9. Package hammering

Package hammering is the most important and difficult step in gold leaf production because it requires high experience and skill in beating. The package hammering must focus the hammer position regularly by arranging 5 packages in 5 horizontal rows and 5 vertical rows, totally are 25 packages until completion of gold packages. To expand the gold, the package must be beaten in every side to heat all sides then beat at the middle of package which has the gold, called gold pressing. The hammering process must be done with regular force, otherwise, the gold will not be expanded and will be broken. Too much repeat may cause the gold stick to that position. There are 2 steps of traditional package hammering, which are แรกทองกับกลอยทอง. The แรกทอง requires 2 beating cycles with 2 hours each, then switch the middle of package with the upper side for regular expansion of gold. Then continue beating for 2 cycles with 2 hours each until ready to remove from the cellophane, which is called gold pouring process. |

|

|

| |

|

|

|

10. Gold pouring

Gold pouring is the process to move the gold from cellophane to protection paper or membrane for cutting purpose. Gold pouring requires professional skill because the beaten gold is very thin and easy to damage. So the gold must be poured slowly and carefully from cellophane to protection paper before transferring to cutting process. |

|

|

| |

|

|

|

11. Gold cutting

Gold cutting requires high skill person because he/she must estimate the middle of gold leaf to be separated. Wrong estimation will cause the gold leaf become tiny spall and get lose. The gold leaf after hammering is very thin and untouchable, except professional technician who is able to put gold foil into cellophane. The hammered gold leaf will be round. |

|

|

| |

|

|

|

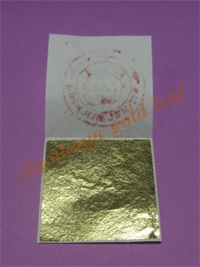

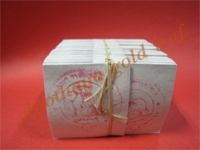

12. Gold bundle

After cutting the gold, we will cross 10 gold sheets then bundle in one group of 100 sheets, and then bundle in large group of 500 sheets. |

|

|

|